“Essential Japanese Saw Types Unveiled: Your Woodworking Companion”

Nokogiri, or Japanese saws, are renowned for their unparalleled accuracy and grace. They utilize a different pull stroke than their Western counterparts, resulting in cleaner cuts with less waste.

Selecting the appropriate Japanese saw might seem daunting, akin to navigating a bamboo forest, due to the numerous blade varieties tailored for different operations. Fear not—this article will provide you with the skills necessary to master any cut!

What is the Main Purpose of Using a Japanese Saw?

Compared to European or Western saws, Japanese saws, or nokogiri, differ in history and design, which is the main reason for their use. Originally designed to cut softwoods like pine and cypress, Japanese saws prioritize dexterity and grace.

The primary use of a Japanese saw is to make accurate cuts in wood. Japanese saws cut on the pull stroke, unlike Western saws, which cut on the push stroke. This design allows for the use of a smaller blade, resulting in finer cuts with less wood waste. They are ideal for precise and clean cuts, such as joinery and delicate cutting.

Varieties Types of Japanese Saws Material and Their Uses?

Each type of Japanese saw is suitable for different applications. Lack of proper information about them often leads to mistakes, which can double the cost of a project. Therefore, it’s crucial to understand the usage of Japanese saws according to their type to avoid unnecessary expenses.

Saw Ryoba (渡刃, ryōba)

Use: Ideal for a variety of woodworking chores, this double-edged workhorse offers versatility. One side features coarser ripping teeth for cuts along the grain, while the other side has finer crosscut teeth for precise cuts across the grain.

Material: Typically made of premium hardened steel for longevity and sharpness. Handle materials may vary, including wood, bamboo, or plastic.

Saw Kataba (片刃, kataba)

Use: Available in various sizes and tooth configurations, the Kataba saw is suitable for specialized cross-cutting or ripping tasks, as well as precision work in cabinetry and general carpentry.

Material: Features a clean-cut, hardened steel blade similar to the Ryoba. Handle material varies based on quality.

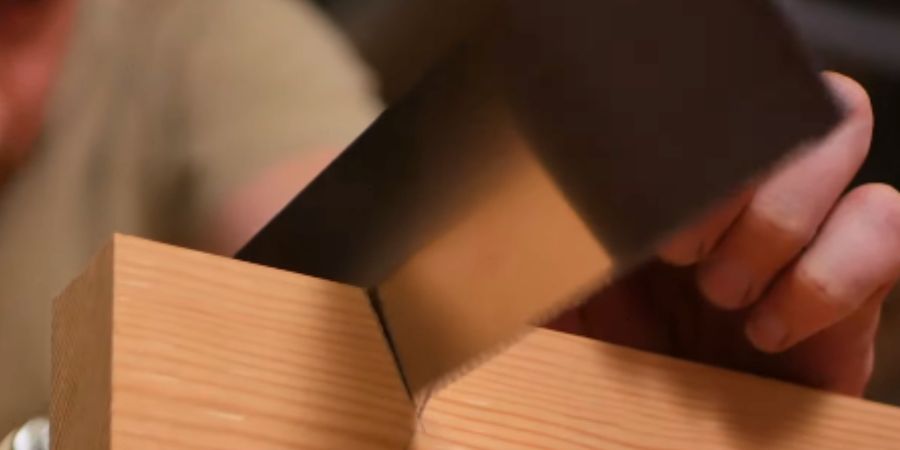

Dozuki Saw, or dōzukinoko (胴付鋸)

Use: Best suited for precise joint work such as dovetails and tenons, requiring extremely clean cuts. Essential for fine woodworking and detail-oriented tasks.

Material: Narrow blade made of high-carbon steel for strength and flexibility. Handles may have wooden or robust backs made of bamboo or hard plastic.

Saw Azebiki (畦挽, azebiki)

Use: Special curved blade designed for conquering even the most difficult plunge cuts, such as sliding dovetails, mortises, and grooves, simplifying joinery operations.

Material: Constructed of premium steel for durability, with bamboo or wood handles for comfort.

Kugihiki Saw (kugihiki saw)

Use: Ideal for making flush cuts without damaging surrounding wood, usually constructed of high-carbon steel with unset teeth on one side. Perfect for driving dowels, nails, or trimming protrusions during finishing.

Material: Requires high-carbon steel for strength and maneuverability. Handle materials vary in quality, from plastic to wood.

Mawashibiki Saw (Compass Saw):

Use: Perfect for creating intricate curves and delicate shapes in intricate tasks, featuring a thin, flexible blade with fine-toothed, high-carbon steel. Handles may be made of plastic or wood.

Nagasa-Biki Saw:

Use: Also known as the “Dovetail Saw,” this specialty tool excels in fine woodworking, guaranteeing unparalleled precision in creating dovetail joints. Made of premium steel with extremely fine teeth, handle material may vary.

Japanese Crosscut Saw Vs Rip Saw?

I am giving you a clear idea of rip saw vs crosscut saw below.

Rip Saw

Intended for cutting in the direction of the wood’s grain. Usually, the coarser teeth on these saws are inclined slightly to grasp and tear the fibers of the wood. In your summaries, this pertains to:

Ryoba (one side): The rip-cut side has teeth that are harsher.Kataba (many types): Certain Kataba saws are made especially for ripping, and they will have a tooth pattern made just for that.

Cross-cut Saw

Intended to cut through the wood’s grain. With their sharper teeth, which function like small blades, these saws produce cleaner cuts with less tear-out. In your summaries, this pertains to:

Ryoba (one side): The cross-cut side has teeth that are finer.Depending on the type, Kataba saws can be used for cross-cutting; these saws will have a tooth pattern that is specifically built for this purpose.

Dozuki: Because of its narrow, sharp blade, this tool is mostly employed for cross-cutting.

Dovetail Saw: The Nagasa-Biki Saw is an excellent tool for cutting the precise crosscuts required for dovetail joints.

You’ve produced an extremely educational resource on Japanese saws by adding these details, which make it obvious which saws are ideal for cross-cutting and rip cuts.

When Are Japanese Saw Origin ?

There’s a clearer picture for the origin of different saw types in Japan:

Crosscut Saws (Before 6th Century): The earliest Japanese saws discovered were all designed for crosscutting wood. These likely emerged sometime before the 6th century.

Rip Saws (Mid-Muromachi Period – 1336-1573): The introduction of rip-cut saws specifically designed to cut along the grain of wood happened sometime during the mid-Muromachi period. This development likely coincided with advancements in Japanese woodworking techniques influenced by Buddhism.

Advantages and Disadvantages of Japanese Saws

Japanese saws have unique features that distinguish them from Western saws. Here’s a summary of their pros and cons:

Benefits

Excellent Cut Quality: Ideal for precision woodworking and joinery, producing clean, precise cuts with minimal tear-out.

- Less Work: Require less effort to operate due to the pull stroke motion.

- Thin Kerf: Minimize waste and remove less wood, suitable for tight cuts.

- Improved Control: Pull-cutting motion allows for effective control, resulting in precise and straight cuts.

- Variety of Blades: Different tooth combinations available for various cutting tasks.

Disadvantages

Learning Curve: Pull-cutting approach may be uncomfortable for those accustomed to Western saws.

- Brittle Teeth: Thin, hard steel teeth can chip or break if used improperly.

- Dust Removal: Regular clearance of sawdust required to maintain visibility.

- Limited Rip Capacity: May not be as effective as Western saws for severe ripping operations.

- Sharpening: Requires specific pull-saw sharpening technique.

Western Saw Vs. Japanese Saw: Which One is the Best?

Western saws excel in strength and cutting through heavy timber quickly, suitable for beginners. However, Japanese saws, with their precise cuts and minimal material removal, are ideal for precision work. The choice between them depends on the project requirements.

FAQ,s

Why Did the Japanese Saws Cut on the Pull Stroke?

Japanese saws are designed to cut on the pull stroke, reducing resistance and enhancing cutting efficiency, resulting in a thinner blade and narrower kerf while maintaining precision.

Can Japanese Saws Be Used for Hardwoods, or Are They Better Suited for Softwoods?

While Japanese saws were originally intended for softwoods like cypress and pine, they can be used on hardwoods as well. However, European saws designed for hardwoods may perform better in some cases.

Are There Safety Precautions to Consider When Using Japanese Saws?

Safety should be a priority when working with Japanese saws, as their fine teeth can break when cutting through dense or knotty wood. Safety goggles are recommended, along with gentle handling and control of the saw.

Can Japanese Saws Be Used for Large-scale Woodworking Projects, Such as Timber Framing?

Yes, Japanese saws can be effectively used in substantial woodworking projects like timber framing, offering reach and cutting capacity suitable for larger-scale tasks.

Conclusion

Japanese saws offer woodworkers unparalleled precision and clean cuts with minimal waste, making them invaluable tools for woodworking projects. Despite their initial complexity, they are surprisingly simple to use with practice. While Western saws excel in power, Japanese saws are renowned for their accuracy and are ideal for intricate detailing.

Read also:

Straight Peen Hammer Uses: From Metalworking to Jewelry Making