Combination Pliers Uses Explained: Features, Types, and Applications

Pliers are indispensable tools, primarily designed to provide a strong, secure grip on materials that are too difficult or too small to handle with bare hands. With their ergonomic design and robust construction, pliers allow users to twist, bend, cut, and manipulate materials with precision and control. Among the many types of pliers available, combination pliers stand out as the most versatile and widely used option.

Whether you’re working on electrical wiring, plumbing, or simple DIY tasks, combination pliers offer a reliable solution for a range of tasks. In this guide, we will explore the unique features and uses of combination pliers, equipping you with the knowledge to utilize them effectively in your day-to-day projects.

What is a Combination of Pliers?

A combination plier is a multifunctional hand tool engineered for both gripping and cutting tasks, making it indispensable across various trades. Its key features include:

- Serrated Jaws designed for a firm grip on flat or cylindrical objects.

- High-leverage Cutters strategically placed near the pivot for efficient wire or cable cutting.

- Optional Enhancements, such as pipe grips or wire stripping notches, to broaden its utility.

Originating from early blacksmithing tools, modern combination pliers are crafted from advanced alloys like chrome vanadium steel for durability and precision. They serve professionals in construction, electrical work, and mechanical repair with unmatched reliability and versatility.

What Type of Material is Made From Combination Pliers?

Combination pliers are made from high-strength materials designed for durability and performance. The main body is typically crafted from chrome vanadium steel (CR-V), valued for its exceptional hardness, corrosion resistance, and tensile strength, making it ideal for professional use. Some models use high-carbon steel, offering good cutting capability but requiring protective coatings like black oxide or chrome plating to prevent rust.

Handles are coated with rubber, plastic, or thermoplastic elastomers (TPE) for enhanced grip and user comfort. These materials ensure the pliers can endure heavy-duty tasks while providing a secure and ergonomic handling experience.

Different Types of Combination Pliers and Their Uses

Combination pliers come in many different types, each designed for a specific application, making them an essential tool for professionals in various fields. Below are some of the most common types and their uses:

Standard Combination Pliers

The most common and versatile type, designed for general-purpose tasks. These pliers feature serrated jaws for gripping and integrated cutters for cleanly cutting wires and small materials.

They are best suited for gripping flat or cylindrical objects, bending soft metals, and cutting cables, making them an essential tool for household repairs, DIY projects, and basic electrical work. Their simplicity and reliability make them a staple in any toolkit.

Insulated Combination Pliers

Specifically designed for safety in electrical work. These pliers are equipped with handles insulated to withstand up to 1000 volts, making them essential for electricians working with live wires.

They are ideal for electrical installations, repairs, and maintenance tasks, ensuring safety while handling high-voltage systems. Their durability and safety features make them a must-have for professionals in the electrical industry.

Long Nose Combination Pliers

These pliers feature elongated, tapered jaws that allow for precision work and access to tight or recessed spaces.

They are perfect for handling delicate wires and small components and are commonly used in electronics assembly, jewelry making, and intricate repair tasks. Their precise design makes them invaluable for professionals who need to work in confined areas or with small, intricate materials.

Heavy-Duty Combination Pliers

Built for tough applications, featuring reinforced jaws and pivot points. They are designed to handle thick wires, bolts, and heavy materials with ease.

These pliers are best suited for construction, industrial maintenance, and mechanical repairs, where strength and durability are essential. Their robust construction ensures they can withstand rigorous use in demanding environments.

Fencing Combination Pliers

Specialized tools for agricultural and fencing tasks. These pliers combine multiple functions, including gripping, cutting, and hammering. They are ideal for securing, cutting, and tensioning fencing wires and are widely used in farm maintenance and boundary installations.

The addition of a hammering face makes them a one-tool solution for many fencing tasks, saving time and effort for ranchers and agricultural workers.

Parallel Action Combination Pliers

These pliers feature jaws that close in a parallel motion, providing even pressure across the gripping surface. This design makes them ideal for gripping delicate materials without causing damage and for applying significant force when cutting.

These pliers are commonly used in precision engineering, model making, and tasks requiring consistent grip and leverage. Their unique mechanism offers superior control and efficiency.

Multifunctional Combination Pliers

These pliers integrate additional features such as wire strippers, crimpers, and nail pullers. Designed for versatility, they are suitable for stripping wire insulation, crimping connectors, and pulling nails during carpentry or construction work. Their all-in-one functionality makes them highly efficient for professionals who need a compact tool that can handle multiple tasks with ease.

Each type of combination pliers has its own strengths and applications. Based on my extensive experience with these tools in various professional settings, I can attest to their importance in simplifying work. Choosing the right pliers for the job ensures not only efficiency but also durability and safety, making them an invaluable asset in any toolkit.

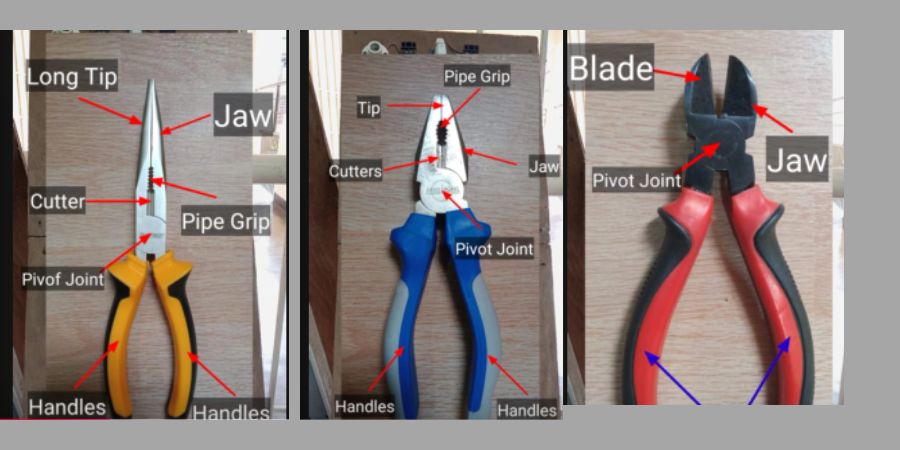

What Are the Different Parts of Combination Pliers?

Combination pliers are a staple in the toolkits of professionals and DIY enthusiasts, prized for their versatility and robust design. Below, I’ve explored their different parts, offering technical insights and practical skills based on years of experience operating these tools.

Handles

Handles are the user interface to the pliers. Typically coated with rubber or plastic, they provide comfort and a firm grip, essential during prolonged use. Heated versions are rated up to 1000 volts, making them essential for electricians. Proper handle design reduces hand fatigue, especially when working on tough materials like 8-gauge wire.

Pivot Point

Located in the center of the tool, the pivot point is the hinge mechanism that converts hand force into amplified jaw action. Its positioning is critical—close to the cutting edge for optimal leverage. A well-maintained pivot ensures smooth operation and prevents binding during tasks such as cutting tough steel wire (up to 2.5 mm diameter).

Jaws

The serrated jaws are the workhorse of combination pliers, designed to grip flat, cylindrical, or irregular objects tightly. My experience has shown that high-quality jaws with sharp teeth can grip 1/2-inch pipe or strip insulation from wire without slippage.

Cutting Edge

Located close to the pivot, the cutting edge is a precision feature designed for clean cuts. On properly heat-treated pliers, the edge can cut copper wires up to 12 AWG or mild steel wires up to 16 AWG. This material must be durable, as it takes the most wear during tasks such as cutting fence wire or nails.

Pipe Grip

This semicircular section between the flat jaws and the cutting edge is designed for round materials like pipe or rod. I often use this feature to grip 3/4-inch metal rods during assembly projects, finding it to be reliable even under pressure.

Wire Stripper (Optional)

Some combination pliers come with a wire stripper, with notches for specific gauges of wire insulation. This tool is a lifesaver when working with 10 to 20 AWG wire, allowing electricians to strip without damaging the core. I found them invaluable for preparing connections in control panels.

Nail Puller (Optional)

A small but powerful feature, the nail puller is great for pulling out nails embedded in wood or other materials. During my carpentry project, this feature saved me time when pulling out a 2-inch finishing nail without damaging the wood surface.

Jaw Tips

The pointed tips are designed for precision work, such as bending small wires or gripping small components. I used them extensively to bend the ends of 18 AWG wires when connecting to terminal blocks, finding their precision unmatched.

Why Understanding These Parts is Important

Each component of a combination pliers is carefully designed to meet specific needs, from gripping and cutting to precision bending. By understanding these parts, users can maximize their functionality and longevity, ensuring they perform reliably in demanding situations. With proper maintenance and material selection (e.g., chrome vanadium steel), I believe these tools are a long-term investment for both professionals and hobbyists.

How to Use Combination Pliers?

Using combination pliers efficiently requires a solid understanding of their design and the function at hand. As an experienced tool user, it is essential to leverage the versatility of these pliers for a variety of tasks, ensuring not only precision but also safety and durability in your work. Let’s take a look at how to use them in different situations.

Gripping and Bending Wire

When it comes to gripping and bending wire, place the wire firmly between the flat parts of the jaws. The serrated teeth will help to grip the wire securely, allowing for precise bending. The leverage provided by the pivot point gives excellent control when shaping the wire, ensuring that you do not overstretch or deform it. Be mindful of the pressure applied, as excessive force can damage the wire or compromise your grip.

Cutting Wire or Cable

For cutting, always make sure the wire is placed on the cutting edge of the pliers. Keep it close to the base for maximum leverage. Squeeze the handles with steady force to create a clean cut without damaging the surrounding material. The cutting edges of high-quality combination pliers made from high-carbon or alloy steel provide the sharpness needed for clean cuts. It is essential to maintain the cutting edge by using the pliers only for their intended purpose and avoiding overloading them with larger, harder materials.

Removing Nails and Fasteners

Pulling out nails or fasteners is one task where combination pliers really shine. Place the head of the nail between the jaws and use the handles as leverage to free it. The force applied to the pivot point, combined with the grip of the jaws, allows for efficient extraction. This is especially useful in carpentry or demolition work, where speed and precision are important. It is important to keep a steady grip on the tool to avoid slipping, which can damage the material or cause injury.

Stripping Wire Insulation

If your combination pliers are equipped with wire strippers, this feature should be used with great care. Place the wire in the appropriate groove and apply light pressure to remove the insulation without damaging the core. This feature is essential in electrical work, where precision stripping is necessary. As with all work, make sure the jaws of the pliers are properly aligned to prevent nicking or breaking the wire.

Gripping Round Objects (Pipe Grip)

For work involving pipes, rods, or other cylindrical materials, the pipe grip section of the jaws comes in handy. This part of the pliers is designed to securely hold round objects without causing any damage. Use this grip to turn or hold pipes while working, tightening, loosening, or adjusting. The shape of the grip ensures that the materials do not slip, which is very important in plumbing or mechanical repairs where precision is required.

Precision Work Using Tips

The very tips of combination pliers are essential for more delicate and detailed work. They are best used for tasks that require extra control, such as bending small wires or handling small components. Their precision makes them ideal for working in tight or confined spaces, giving you a clear advantage when performing detailed tasks such as soldering, wiring, or fine adjustments.

Safety and Maintenance

A well-maintained set of combination pliers can last for years, but it is essential to use them correctly to ensure their longevity. Always keep the jaws clean and free of rust or corrosion by wiping them down after use. Regularly inspect the handles for wear and make sure the pivot point is well lubricated for smooth operation. Safety should always be your top priority—wear gloves and eye protection when working with heavy-duty tasks to prevent injury from debris or accidental slips.

Read also: