Pipe Wrench Vs Channel Locks

Decoding the Pipe Wrench and Channel Lock Dilemma, When is it best to reach for a pipe wrench, and when should channel locks take center stage?

This article unravels the mystery behind these indispensable tools, offering a side-by-side comparison of their features, applications, and potential pitfalls. Equip yourself with the knowledge to make informed decisions and ensure your next project flows smoothly.

What Are Pipe Wrenches Used for?

A pipe wrench is a versatile tool widely used for gripping and turning pipes and fittings. Its adjustable serrated jaws make it suitable for various applications, including:

- Metal Pipes and Fittings: Ideal for tightening or loosening connections on steel or iron pipes.

- Large Diameter Pipes: Provides leverage for working with larger pipes.

- Tight Spaces: Effective in confined or hard-to-reach areas.

- Rounded or Irregular Shapes: Conforms to the shape of pipes with irregular contours.

- Secure Gripping: Prevents slippage, ensuring a secure grip on cylindrical objects.

- Plumbing Work: Commonly used in plumbing installations and repairs.

- Construction and Maintenance: Valuable in construction and maintenance tasks involving pipes.

- Versatile Materials: Suitable for various materials, including metal and some plastics.

- General Purpose Wrench: Acts as a general-purpose wrench in various applications.

While versatile, choosing the right tool for specific materials is essential to avoid damage. Avoid using it on PVC or delicate materials, opting for alternative tools like pliers when necessary.

What Are Channel Locks Used for?

Channel locks, or tongue-and-groove pliers, are versatile tools crucial for gripping, turning, and shaping tasks. With an adjustable jaw, they excel in fastener manipulation, ideal for plumbing and general maintenance.

Beyond nuts and bolts, they prove handy in shaping sheet metal, providing a makeshift clamping function. While not specialized, their robustness accommodates light sheet metal bending.

In electrical work, they find utility in gripping and manipulating wires, providing a robust and adjustable grip. Channel locks showcase adaptability, making them indispensable in various industries, from metalworking to electrical installations, offering a multifaceted solution for manual tasks.

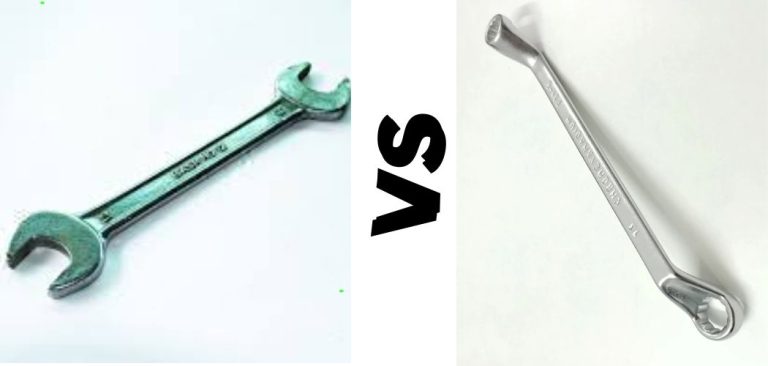

What is the Actual Difference Between Pipe Wrench and Channel Locks?

Pipe wrenches and channel locks are hand tools used in plumbing and other applications, but they serve different purposes and have distinct characteristics. Here is a comparison between the two:

Shape:

Pipe Wrench: The pipe wrench has an adjustable jaw and a long handle. The jaws are pointed and designed to grip round objects such as pipes.

Channel-lock: Channel lock, or tongue-and-groove pliers, have adjustable jaws similar to a pipe wrench but are usually shorter and have a thinner profile. They can be adjusted to grip different objects.

Ingredients:

Pipe Wrench: Usually made of heavy-duty materials such as cast iron or aluminum for durability.

Channel Lock: Made of chrome-vanadium steel for strength and durability.

Compatibility:

Pipe Wrench: Adjusts by turning the knurled adjusting nut on the handle, allowing the jaws to open or close.

Channel Lock: Adjustable by sliding the pivot point along a track, allowing for a range of jaw openings.

Ideal application:

Pipe Wrench: The pipe wrench emerges as a precision instrument tailored for gripping and bending pipes with finesse. Its robust and large serrated jaws deliver an unyielding grip on cylindrical objects, providing the necessary torque for tasks specific to pipes and fittings.

Channel Locks: In contrast, channel locks step into the spotlight as versatile maestros, seamlessly adapting to various tasks. Their ideal application extends to gripping and turning various shapes, from pipes to nuts, bolts, and even irregularly shaped objects.

Origin:

Pipe Wrench: The pipe wrench has a long history and is associated with the American tool company Stilson, which patented the design in the 19th century.

Chanel Lock: The term “Chanel Lock” is often associated with the Chanel Lock brand, which is an American company. However, tongue-and-groove pliers have a long history and are used by a variety of manufacturers.

Price:

Pipe Wrench: Prices may vary based on size, brand, and material, Basic models start around $20, while premium and specialized versions can command prices exceeding $100.

Channel Locks: Prices may vary based on size, brand, and material; basic models start around $15, with higher-end or specialized versions reaching $50 or more.

Legal Differences:

There is generally no legal difference between the two tools. However, patents or trademarks may protect designs and brands, depending on the manufacturer.

Other Considerations:

Pipe Wrench: Due to its design, it can leave marks on the pipe surface.

Channel Lock: Adjustable jaws allow for a wide range of applications but can’t provide a grip on pipes as tight as a pipe wrench.

In summary, although pipe wrenches and channel locks are both adjustable tools used for gripping and bending, pipe wrenches are designed specifically for large or irregularly shaped pipes.

In contrast, channel locks are more versatile and can handle different objects. The choice between the two depends on the specific application and personal preference.

How Can We Avoid Using Pipe Wrenches and Channel Locks in the Wrong Places?

The key is precision when tackling the delicate task of opening a stripped nut or thread on a small or medium toilet water line. In such situations, using a pipe wrench or channel locks might seem like the go-to solution, but it’s a common mistake. These heavy-duty tools can exert excessive force, potentially causing further damage.

To navigate the nuances of smaller nuts and bolts, opting for a more finesse-oriented approach is crucial. A box or adjustable wrench is the tool of choice in these scenarios.

Their compact design and adjustable features make them ideal for the intricate work involved, ensuring you can address the issue without causing unnecessary strain on the plumbing components.

Moreover, the challenges multiply when dealing with stubborn mechanisms that require a clockwise rotation to open. Pipe wrenches and channel locks, designed for larger applications, often struggle in these confined spaces and are prone to slipping.

This is where the versatility of an adjustable wrench shines. Its adaptable jaw width and secure grip provide the control needed to navigate tight quarters and handle clockwise rotations with ease.

In essence, avoiding the mistake of using pipe wrenches and channel locks in the wrong places involves recognizing the specific demands of the task at hand.

By employing the right tools, such as box wrenches and adjustable wrenches, you not only safeguard the integrity of the plumbing but also streamline the repair process, making it more efficient and effective.

FAQs

How Does a Pipe Wrench Work?

The Stillson wrench, a common type of pipe wrench, has adjustable jaws with hardened teeth. These teeth bite into the softer metal of the pipe, providing a solid grip. The adjustable jaw design allows intentional play out of the square, enabling it to bind to the pipe. Forward pressure on the handle tightens the jaws.

Can a Pipe Wrench Be Used on Hex Nuts or Other Fittings?

While not intended for regular use on hex nuts, a pipe wrench can be adequate if a hex nut becomes rounded or stripped. The wrench’s design allows it to bite into rounded metal surfaces, making it a valuable tool in such situations.

What Sizes Are Available for Pipe Wrenches?

Pipe wrenches come in various sizes, typically ranging from 6 inches (150 mm) to 48 inches (1,200 mm) or even larger. The size is determined by the length of the handle, offering versatility for different pipe diameters.

What is the History of the Pipe Wrench?

The first pipe wrench, known as the Stillson wrench, was created by Daniel C. Stillson in 1869. The wrench became widely used for turning pipes. Another inventor, Johan Petter Johansson, patented the adjustable pipe wrench in 1888, providing a tool capable of gripping nuts of different dimensions due to poorly standardized nut sizes.

How Does a Pipe Wrench Compare to Channel Locks?

While both are versatile tools, a pipe wrench is specifically designed for turning pipes and pipe fittings. On the other hand, channel locks are adjustable pliers that can be used for various gripping tasks.

Pipe wrenches provide a secure grip on rounded surfaces, while channel locks offer a broader range of applications with adjustable jaw width. The choice between them depends on the specific task at hand.

Conclusion

In conclusion, choosing between a pipe wrench and channel locks hinges on the task. While pipe wrenches excel in precision tasks involving pipes and fittings, channel locks showcase adaptability across various applications.

Understanding their differences, materials, and ideal uses is critical to avoiding common mistakes. By selecting the right tool for the job, one ensures efficiency, effectiveness, and the longevity of both tools and projects.

Read also:-