Ratchet vs Wrench

When it comes to tightening or loosening bolts and nuts, two popular tools immediately come to mind: ratchets and wrenches. Although these tools are often used interchangeably by beginners, each has unique advantages that make it more suitable for certain tasks.

Understanding the differences between a ratchet vs wrench can help you work more efficiently and achieve better results. This blog will dive into the details of both tools, exploring their individual strengths and the best scenarios for each use. Let’s get down to the nitty-gritty.

What is the Actual Difference Between Ratchet vs Wrench

The real differences between a ratchet and a wrench come down to their design, functionality, and the type of work they excel at. Here’s a detailed look at the key differences between them and why they are different from each other.

Design and Structure

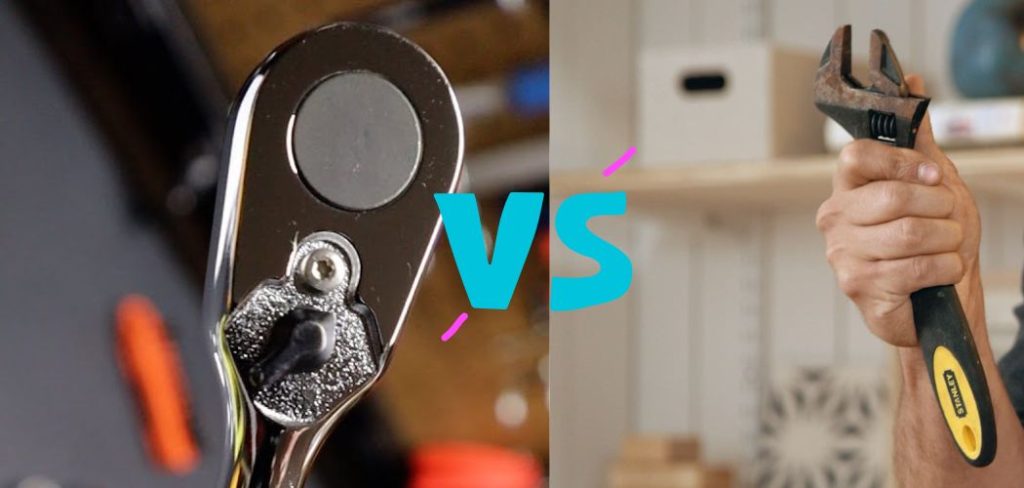

- Ratchet: A ratchet is a tool with a socket attached to a handle and a ratcheting mechanism, allowing it to turn in one direction while remaining fixed in the opposite direction. This feature enables you to tighten or loosen bolts without removing the tool and repositioning it after each turn. Typically, the ratchet has a square drive at the end where you can attach various socket sizes.

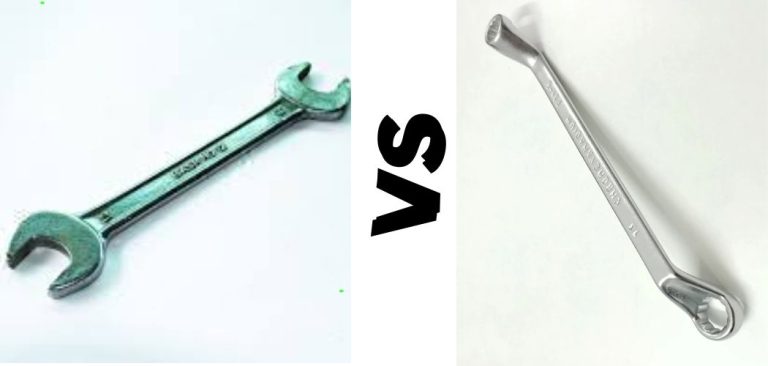

- Wrench: A wrench is generally a solid tool with an open or closed end that grips a bolt or nut. Wrenches come in various types, such as open-end wrenches, box-end wrenches, and combination wrenches. Unlike ratchets, they lack a ratcheting mechanism, meaning you often need to reposition the wrench after each partial turn.

Functionality and Use

- Ratchet: Ratchets excel in confined spaces where there’s limited room to maneuver. Thanks to their ratcheting mechanism, they allow for a back-and-forth motion, meaning you can work on a bolt or nut without having to remove the socket. This feature makes ratchets highly efficient in automotive work and any project requiring repetitive tightening or loosening of bolts in tight areas.

- Wrench: Wrenches are often more versatile in terms of access and simplicity. They can be quicker to use when there’s enough space to work with since there’s no need to attach a socket. Wrenches are great for larger bolts or when you need greater torque, as you can apply more force without relying on a smaller ratcheting mechanism.

Strength and Durability

- Ratchet: Ratchets are usually designed to handle moderate levels of torque, though heavy-duty ratchets can manage high-torque jobs. They are ideal for work that requires consistent, smooth motion rather than high power.

- Wrench: Due to their solid build, wrenches can handle much higher levels of torque, making them suitable for heavy-duty work. If you need to apply a lot of force, such as breaking a rusted bolt, a wrench may be the better choice, as there’s less risk of damaging a ratcheting mechanism.

Best Scenarios for Use

- Ratchet: Best for repetitive tasks, automotive repairs, and jobs in tight spaces. The ratchet is ideal when you need speed and efficiency, especially in confined areas where a full turn of a wrench isn’t possible.

- Wrench: Ideal for situations that require high torque or don’t allow the extra depth a ratchet and socket may need. Wrenches are better suited for heavy-duty, industrial tasks or large bolts that need significant force.

Origins and Evolution

- Ratchet: Ratchets were designed to improve efficiency in repetitive tasks, evolving with the automotive industry’s need for faster and easier ways to handle nuts and bolts. The ratcheting mechanism has been improved over time for durability and ease of use.

- Wrench: Wrenches have a much older origin, dating back centuries. Their basic design has remained largely unchanged, with variations like the adjustable wrench and box-end wrench created for specialized uses. Wrenches were and are valued for their strength and simplicity.

Advantages and Disadvantages:

| Feature | Ratchet | wrench |

| Ease of Use | High in tight spaces | Good in open spaces |

| Torque | Moderate | High |

| Speed | Faster for repetitive tasks | Can be slower for repetitive tasks |

| Versatility | Depends on socket set | Available in various types |

| Durability | Moderate (due to moving parts) | Very high |

In short, if you’re working on tasks requiring speed and maneuverability, like auto repairs, a ratchet is your best choice. If you need high force and durability, a wrench might be the better tool.

Comparing Specific Tools: Ratchet vs Wrench Types

Open-end Wrench vs Standard Ratchet

An Open-End Wrench has a U-shaped opening that grips two opposite sides of a fastener. It’s ideal for situations where you need to tighten or loosen a fastener quickly without encircling it, making it useful in areas with limited clearance on one side.

A Standard Ratchet has a reversible gear that allows continuous turning in one direction, making it faster and easier to use, especially when a full rotation is restricted.

While the open-end wrench offers quick access and a secure grip, the standard ratchet’s ratcheting mechanism makes it more efficient for repetitive tightening and loosening, especially in limited spaces where a wrench’s partial rotation might slow you down.

Box-end Wrench vs Flex-head Ratchet

A Box-End Wrench encloses the head of a fastener, providing a solid grip for applying greater torque. It’s perfect for breaking loose stubborn bolts or nuts without the risk of slipping.

A Flex-Head Ratchet has a pivoting head, which allows it to access fasteners at difficult angles or in tight spaces, providing flexibility that most wrenches cannot match.

The box-end wrench provides better torque control, making it ideal for high-resistance fasteners, while the flex-head ratchet shines in awkward or confined spaces, allowing you to reach bolts without needing perfect alignment.

Adjustable Wrench vs Swivel-Head Ratchet

An Adjustable Wrench with a movable jaw can adapt to different sizes of fasteners, eliminating the need for multiple wrenches. It’s commonly used in general repairs but doesn’t provide the most secure fit for high-torque tasks.

A Swivel-Head Ratchet has a rotating head, enabling better maneuverability around tight corners. The swivel design makes it suitable for working around obstacles where a standard wrench or ratchet may not fit.

Comparison: The adjustable wrench is versatile in terms of fit but lacks the torque and security of a fixed-size wrench. The swivel-head ratchet, however, is better suited for complex, cramped spaces, offering flexibility that’s hard to match with an adjustable wrench.

Pipe Wrench vs Powered Ratchet (Electric/pneumatic)

A Pipe Wrench, known for its serrated jaws and adjustable head, is used mainly for rounded surfaces, such as pipes and fittings, providing a strong grip on cylindrical objects.

A Powered Ratchet (available in electric or pneumatic versions) reduces manual labor by providing automated fastening. They’re commonly used in automotive and industrial settings where speed is essential.

Comparison: The pipe wrench is ideal for plumbing work and other tasks involving round objects, where a standard wrench or ratchet would slip. The powered ratchet is unmatched in speed and efficiency for tightening and loosening bolts in large quantities but isn’t suited for rounded surfaces or high-torque applications.

Torque Wrench vs Torque Ratchet

A Torque Wrench allows precise control over the torque applied to fasteners, making it essential for situations where exact torque settings are required (e.g., engine assembly or equipment calibration).

A Torque Ratchet combines the ratcheting function with torque settings, allowing you to tighten bolts to a specific level of torque without having to remove the tool.

Comparison: Both tools offer control over torque, but the torque ratchet’s ratcheting mechanism makes it more efficient for repetitive tasks, while the torque wrench provides more direct control, which may be preferable in delicate applications.

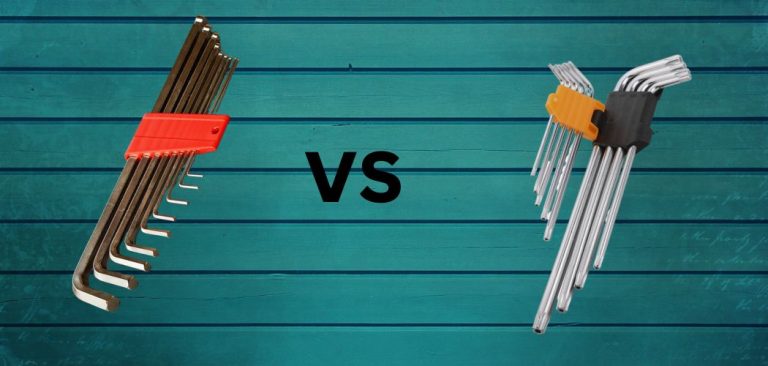

Allen Wrench (Hex Key) vs Stubby Ratchet

An Allen Wrench (Hex Key) is an L-shaped tool specifically used for hexagonal socket screws, commonly found in furniture assembly and machinery maintenance. Its compact design allows it to fit in small spaces.

A Stubby Ratchet is a shorter-than-average ratchet that works well in tight areas with minimal clearance for larger tools.

Comparison: The Allen wrench is suited for hex screws in very confined spaces but requires more effort and time for larger tasks. The stubby ratchet, while slightly larger, is far more efficient in confined spaces where traditional ratchets or wrenches may not fit, especially for standard bolts and nuts.

Read also: