Aviation Snips vs Tin Snips: An Expert Analysis for Precision Metal Cutting in 2025

Selecting the appropriate tool is crucial for achieving efficient, precise, and safe results when cutting metal. Among the essential hand tools in metalworking, aviation snips and tin snips are commonly used, each with unique features and specific applications. While both are designed to cut sheet metal, understanding their differences is key to optimizing performance and minimizing effort.

This report offers a concise comparative analysis of aviation snips and tin snips, integrating recent innovations and user insights from 2025 to guide professionals and serious DIYers in making informed tool choices.

Aviation Snips Features and Functionality in 2025

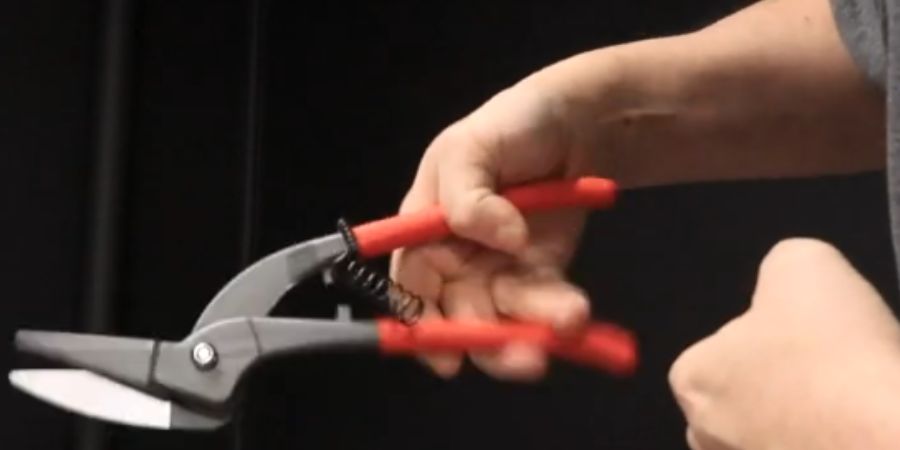

Aviation snips, or compound snips, use a compound leverage mechanism with multiple pivot points to cut thicker metals with reduced hand strain. Their color-coded handles—red for left, green for right, and yellow for straight cuts—allow quick tool identification. Serrated blades ensure secure grip and cleaner cuts, while safety latches keep blades closed during storage.

Three standard types are available: straight-cutting for straight lines and wide curves, left-cutting (red handles) for counter-clockwise curves, and right-cutting (green handles) for clockwise curves. Specialized variants include offset snips (angled blades for hand clearance), vertical snips (90° blades for tight spaces), bulldog snips (short, strong blades for seams and thick metals), and long-cut snips (extended blades for uninterrupted cuts).

In 2025, innovations like the Midwest Blackout Series offer black oxide-coated blades for rust resistance. The Crescent Wiss Next Generation snips last up to 60% longer and require 20% less cutting force, with ergonomic features like improved latches and handle rings.

Milwaukee models feature a one-handed locking mechanism and flush bolts. ToughBuilt snips have forged blades lasting 10x longer and dual-position handles. Klein Tools now includes an integrated wire cutter notch, reflecting the trend toward multifunctionality and user-focused design.

Tin Snips Design and Utility for Metal Cutting in 2025

Tin snips, also known as straight snips or tinners, feature a traditional scissor-like design with a single pivot point, long handles, and shorter blades. They excel at making straight cuts and gentle curves in thinner gauge metals.

However, without a compound leverage mechanism, tin snips require more manual force, especially for longer cuts or thicker materials. They are ideal for working with larger metal sheets and simpler tasks where extreme precision or heavy-duty performance is not essential.

In 2025, tin snips are available in several patterns: straight snips for linear cuts, duckbill snips with tapered blades for sharper curves, and curved snips designed for both clockwise and counter-clockwise curved cuts. While the basic design remains unchanged, manufacturers have prioritized comfort by integrating ergonomic, non-slip plastic or rubberized handles.

Blades made from chrome vanadium steel are commonly used, offering durability and precision. Their familiar design makes tin snips accessible to users of all skill levels, contributing to their ongoing popularity.

Market trends show steady growth, driven by global construction and infrastructure projects. The addition of ergonomic enhancements reflects a broader 2025 industry focus on improving comfort and reducing user fatigue, even for traditional hand tools.

Cutting Edge Differences, Aviation Snips Vs Tin Snips

In 2025, aviation snips and tin snips differ significantly in cutting performance, particularly in sharpness, durability, and material compatibility.

Aviation snips use forged alloy steel blades, maintaining sharpness longer and resisting wear, especially due to their compound leverage mechanism which reduces blade strain. Tin snips, while reliable for softer, thinner metals, often require more frequent sharpening unless upgraded with chrome vanadium steel blades.

Aviation snips excel with tougher materials—handling 18-gauge cold-rolled steel and 22-gauge stainless steel with ease. Specialized variants like the Midwest Special Hardness series are optimized for hardened metals. Tin snips perform best with softer materials such as aluminum and copper, up to 20-gauge. Using them on thicker metals increases fatigue and risks tool damage.

User feedback emphasizes the importance of selecting snips based on both material and specific tool quality. With increasing specialization, aviation snips are now tailored for high-performance cutting in demanding scenarios.

| Material Type | Thickness Range | Recommended Snip Type |

| Aluminum | Up to 20 Gauge | Tin Snips |

| Copper | Up to 20 Gauge | Tin Snips |

| Cold-Rolled Steel | Up to 20 Gauge | Tin Snips, Aviation Snips (Straight) |

| Cold-Rolled Steel | 18–22 Gauge | Aviation Snips (Straight, Offset) |

| Cold-Rolled Steel | Thicker than 18 Gauge | Aviation Snips (Bulldog) |

| Stainless Steel | Up to 24 Gauge | Aviation Snips (Straight, Offset) |

| Stainless Steel | Thicker than 24 Gauge | Aviation Snips (Bulldog, Specialized) |

Ergonomics, Ease of Use, and Safety and User Experience in 2025

Aviation and tin snips are seeing advancements in ergonomics to reduce fatigue and improve user comfort. Aviation snips commonly feature ergonomic handles with non-slip grips and finger grooves, while their compound leverage mechanism minimizes manual effort.

Tin snips, though simpler, now often include cushioned or rubberized handles to enhance comfort during prolonged use, though they still require more hand strength, especially for thicker materials.

A key safety feature in both types is a locking latch to secure the blades during storage, helping prevent accidental injuries. Updated safety standards highlight the use of PPE—gloves and safety glasses—as essential. Cutting away from the body and using the appropriate snip type is critical to avoid tool damage and ensure clean results. The rise of ergonomic and safety-focused designs reflects a growing industry trend toward prioritizing user experience.

Applications in Contemporary Metalworking

Aviation snips are essential across HVAC, automotive, and construction industries for cutting ductwork, sheet metal, and roofing. Their ability to handle straight, curved, and complex cuts makes them ideal for confined or intricate tasks, including metal art and robotics. Specialized models—like offset and vertical snips—expand their use in tight spaces and precision applications.

Tin snips, while simpler, remain popular for DIY, crafting, and home repair projects that involve long, straight cuts in thinner metals. Their ease of use and affordability make them suitable for non-professionals and less demanding tasks.

The continued prominence of aviation snips in professional settings underscores their reliability and adaptability. Meanwhile, the sustained use of tin snips for basic, lighter-duty tasks highlights their relevance in simpler metalworking applications. The growing range of aviation snip types reflects industry efforts to meet specialized needs and improve performance in challenging environments.

Maintenance for Optimal Performance and Longevity

After each use, clean off metal debris and moisture with a cloth, and store in a dry area to prevent corrosion. Periodically oil the pivot bolt with light machine oil to ensure smooth operation. While no major new maintenance products have emerged in 2025, cleaning, drying, and lubricating continue to be best practices.

Sharpening should be done using a fine file or sharpening stone, carefully following the original blade angle from pivot to tip. Avoid over-sharpening, as it weakens the blade. Specialized alloy steel sharpening tools are available, but manual sharpening remains effective. Do not use scissors-style sharpeners, as they are unsuitable for metal snips’ geometry and hardness.

Experts advise avoiding fully closing the jaws during cuts to reduce blade wear and improve cut quality—highlighting proper technique as part of effective tool maintenance.

Frequently Asked Questions

Are tin snips the same as aviation snips?

No, tin snips and aviation snips are distinct tools. Tin snips have a traditional scissor-like design and are best suited for straight cuts on thinner materials. Aviation snips, on the other hand, feature a compound leverage mechanism for cutting thicker materials and are available in straight, left, and right cutting designs for greater versatility.

What is an aviation snip used for?

Aviation snips are primarily used for cutting sheet metal. Their design, particularly the compound leverage and various cutting styles, makes them suitable for a wide range of applications, including cutting curves and thicker gauges of metal.

What is the best snip for steel studs?

For cutting steel studs, aviation snips are generally recommended, especially straight-cutting models with compound leverage. Their power and design allow for easier and cleaner cuts through the metal.

What is the difference between aviation snips and offset snips?

Standard aviation snips have blades that are in line with the handles, while offset snips have angled blades. This offset design provides clearance for the user’s hand, making it easier to cut large sheets of metal and follow cutting lines without obstruction.

What are aviation snips used for?

Aviation snips are versatile tools used for cutting metal sheets in various industries, including construction, HVAC, and automotive, as well as in DIY and crafting projects.

How do tin snips differ from aviation snips? Tin snips are similar in appearance to scissors and are most effective for making straight cuts on thinner metals. Aviation snips are designed with a compound leverage system, providing more cutting power and versatility for different types of cuts and thicker materials.

Have there been any significant advancements in aviation or tin snip technology in 2025?

Yes, advancements in 2025 include improved blade materials for longer life and better cutting performance (e.g., Crescent Wiss Next Generation ), ergonomic handle designs for increased comfort and reduced fatigue (e.g., Milwaukee, ToughBuilt ), and specialized features like integrated wire cutters (Klein Tools ) and enhanced rust resistance (Midwest Blackout Series ).

What are the latest recommendations for cutting specific new metal alloys used in 2025 with these snips?

While specific recommendations for cutting newly introduced metal alloys in 2025 would require detailed material specifications, general best practices remain: for harder alloys, aviation snips with high-hardness blades (e.g., Midwest Special Hardness ) are recommended. Always consult the tool manufacturer’s guidelines for the recommended cutting capacity for specific materials.

My opinion

Choosing the right tool for your metal cutting needs is crucial. Aviation snips and tin snips each have their strengths. Need straight cuts? Go for tin snips. For curves and tough materials, aviation snips are better. Always consider the project details before picking.

Safety and precision matter most. With the right snips, your metalwork will be efficient and clean. Remember these tips to make your choice easier. Your projects will thank you.

Read also: