Box-end Wrench Uses

A box-end wrench, often known as a ring spanner, is a versatile tool known for securely gripping and manipulating fasteners. Do you know about box-end wrench uses? If you don’t know, then know its uses and different types.

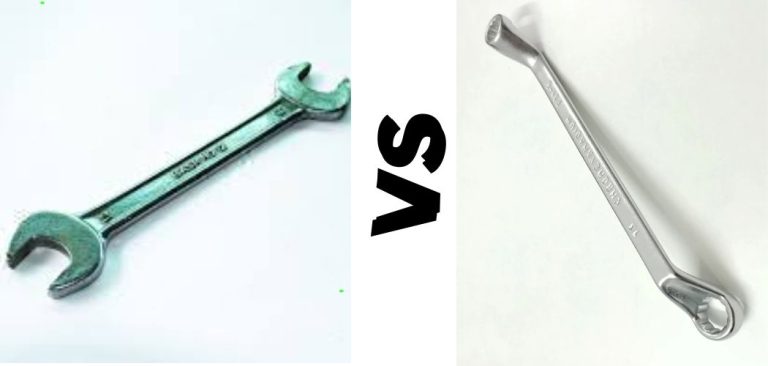

What is a Box-end Wrench?

A box-end wrench, known as a ring spanner, encloses the nut or bolt head with a U-shaped end, providing a secure 360-degree grip. It prevents slipping and damage allows higher torque application, and is available in various sizes.

Its double-ended design offers versatility, while some versions feature ratcheting mechanisms. Common in mechanics and construction, it excels in secure fastening tasks.

Types of Box-end Wrench?

There are different types of box-end wrenches. I describe the advantages of their different sizes below.

Standard Box-end Wrench

The standard box-end wrench is the preferred choice for many applications. Its closed-end design provides better contact with fasteners, reducing the risk of slipping. Available in both 6-point and 12-point configurations, it offers the versatility to engage a variety of nuts and bolts.

12-point Box-end Wrench

Based on the standard design, the 12-point box-end wrench offers more engagement options due to the higher number of points inside the closed end. It can be beneficial when working with fasteners that are difficult to access or have limited clearance.

Offset Box-end Wrench

Offset box-end wrenches are designed with an angle or offset head. This feature allows you to reach fasteners in tight spaces or places where a straight wrench might not fit. The offset design provides an extended reach while maintaining the convenience of a box-end grip.

Ratcheting Box-end Wrench

The ratcheting box-end wrench combines the benefits of a box-end wrench with a ratcheting mechanism. It enables continuous turning without the need to remove the wrench from the fastener. It is precious in confined spaces where a full swing is impossible.

Double Box-end Wrench

A double box-end wrench has two ends enclosed on both sides, each a different size. This dual-sided design eliminates switching between wrenches for different-sized fasteners, making it a convenient option for various jobs.

S-shaped Box-end Wrench

The S-shaped box-end Wrench is designed to provide a comfortable grip and increased leverage. The curved handle allows for a more ergonomic hand position, making applying torque when accessing hard-to-reach fasteners easier.

Flexible Box-end Wrench

The flexible box-end wrench incorporates a flexible joint between the handle and the end of the box. This flexibility enables you to approach fasteners from different angles, accommodating different orientations without compromise.

How to Use a Box-end Wrench?

Here are the steps to use a box-end wrench with a more detailed explanation. This guide will help you to use the box end wrench very easily.

Step 1: Choose the Right Size

Selecting the correct wrench size ensures a snug fit and prevents slipping or damaging the fastener. Look at the sizes marked on the wrench’s head and choose the one matching the nut or bolt you’re working on.

Step 2: Position the Wrench

Hold the box end of the wrench and align it with the nut or bolt head. Ensure that the wrench’s jaws fully cover the sides of the fastener. The open end of the wrench should fit snugly, without any gap between the wrench and the fastener.

Step 3: Apply Turning Force

If the nut or bolt is right-hand threaded (the most common type), you’ll need to turn it clockwise to tighten and counterclockwise to loosen. Firmly grasp the handle of the wrench with one hand, and using the other hand, apply steady force in the direction you want to turn the fastener.

Step 4: Adjust for Limited Space

In situations where there isn’t enough room to complete a full rotation of the wrench, follow these steps:

- When the wrench reaches the limit of its swing, lift it off the nut or bolt entirely.

- Reposition the wrench on the fastener, finding a new angle that allows you to continue turning.

- Apply force again in the desired direction, turning the wrench until it reaches its new swing limit.

- Repeat this process as necessary, lifting and repositioning the wrench to complete the rotation in sections.

Step 5: Final Tightening

After achieving the desired level of tightness or looseness, perform a final tightening. It is significant for critical connections. Use the wrench to apply additional force, ensuring the nut or bolt is securely fastened and won’t lose during use.

Always use the correct wrench size, position the wrench properly, and apply force control to avoid stripping the fastener or damaging the tool. Additionally, be cautious of your hand placement and avoid sudden or excessive force that could lead to injury.

Box-end Wrench Uses

Box-end wrenches, also called ring spanners or closed-end wrenches, stand out as versatile tools that find application in various mechanical and DIY tasks. Famous for their secure grip on fasteners, which helps prevent edge damage, these tools are essential in many situations. Here are some typical applications where box-end wrenches prove their worth:

Automotive Skills

Box-end wrenches find a prominent role in automotive repair. Whether securing engine parts, exhaust systems, or tending to suspension parts, these wrenches provide the torque and grip needed for reliable bolt adjustments.

Cycle Brilliance

Bicycle enthusiasts appreciate the precision that box-end wrenches bring to their craft. From calibrating brakes to fine-tuning gears and other components, these wrenches play a vital role in maintaining optimal bicycle performance.

Plumbing Accuracy

Plumbers rely on box-end wrenches to ensure the tightness of nuts and bolts in plumbing installations. Their secure grip is essential when working with pipes, faucets, valves, and other plumbing fixtures.

Furniture Assembly

The field of DIY furniture assembly benefits from the reliability of box-end wrenches. By securely fastening bolts and nuts, these wrenches ensure the stability of furniture pieces, transforming the assembly process into a more seamless endeavor.

Machinery Maintenance

In industrial settings, box-end wrenches shine during machinery maintenance. The ability to adjust and secure components ensures smooth machine operation and long life, making these tools indispensable in engineering facilities.

Construction Excellence

Box-end wrenches come to the fore on construction sites for tasks such as tightening nuts and bolts in scaffolding, metal framing, and structural components. Their firm grip and straightforward design make them valuable assets in the construction toolkit.

HVAC Harmony

HVAC technicians use box-end wrenches to service air conditioning units, furnaces, and ductwork. The secure grip of these wrenches ensures precise adjustments, contributing to the efficient functioning of the climate control system.

Appliance Efficiency

From fixing washing machines to maintaining refrigerators, box-end wrenches are handy during appliance repairs. Their ability to securely fasten nuts and bolts helps restore the functionality of household appliances.

Diy Joy

The field of DIY projects benefits from the versatility of the box-end wrench. These tools provide the grip and torque needed for various tasks, from assembling furniture to tackling minor household repairs.

Mechanical Marvels

Engineers find box-end wrenches essential for assembling, adjusting, and maintaining machinery in industrial settings. Their reliability helps ensure the accuracy and safety of mechanical systems.

Agricultural Advances

Box-end wrenches are essential in maintaining tractors, farm equipment, and agricultural machinery. Their ability to securely bind ingredients contributes to the efficiency of agricultural operations.

Aeronautical Assurance

Even in the aviation industry, box-end wrenches find their place in aircraft maintenance. Whether tending aircraft engines or working on landing gear, these wrenches provide the reliability and grip needed for critical tasks.

In each of these applications, box-end wrenches prove their versatility and reliability.

Faqs

Do Box-end Wrenches Come in Different Configurations?

Yes, box-end wrenches can have different point configurations inside the head, such as 6, 8, 12, or 16 points. Each configuration is designed to fit specific types of fasteners.

What Materials Are Box-end Wrenches Made From?

Box-end wrenches are typically made from materials like alloy steel or chrome molybdenum steel, which offer durability and strength for demanding tasks.

Can I Use a Box-end Wrench for Left-hand Threaded Fasteners?

Yes, you would reverse the turning direction for left-hand threaded nuts or bolts: turn counterclockwise to tighten and clockwise to loosen.

Conclusion

Box-end wrench uses I temporarily stayed in my friend Suman’s motorcycle garage and organized the article based on my research. If you have any different opinions, then let me know by commenting below. All in all, please share my article with your friends, and I bid you farewell.

Read also:-