How to Remove Bearing from Shaft With Puller: Expert Guide

Removing a bearing from a shaft with a puller is straightforward. This tool simplifies the process, making it more efficient and less damaging.

Bearings are essential components in many machines, ensuring smooth and precise movements. Over time, these bearings may wear out and need replacement. Knowing how to remove them without causing damage is crucial. A puller is a tool designed specifically for this task, making it easier and safer.

In this guide, I will explore the steps to remove a bearing from a shaft using a puller. Whether you are a seasoned mechanic or a DIY enthusiast, this method will save you time and effort. Stay tuned to learn how to do it right.

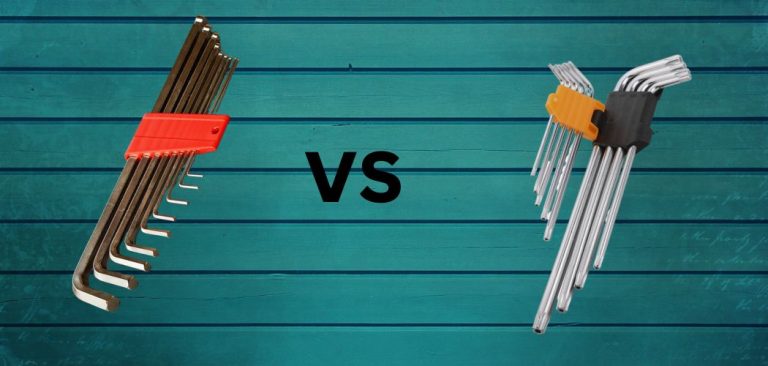

Types Of Bearing Pullers

Removing a bearing from a shaft can be tricky. Using the right bearing puller can make the job easier. There are different types of bearing pullers available. Each type serves a specific purpose. Here, we will discuss the three main types of bearing pullers: Two-Jaw Pullers, Three-Jaw Pullers, and Internal Bearing Pullers.

Two-jaw Pullers

Two-jaw pullers are common and versatile tools. They have two arms, or jaws, that grip the bearing from opposite sides. The jaws are adjustable to fit different sizes of bearings. The center screw pushes against the shaft, pulling the bearing off.

- Easy to use

- Suitable for small to medium bearings

- Can be adjusted for different sizes

Two-jaw pullers are ideal for quick and simple jobs. They provide a firm grip and are easy to maneuver. They are not as stable as three-jaw pullers.

Three-jaw Pullers

Three-jaw pullers provide more stability than two-jaw pullers. They have three arms that grip the bearing evenly. This distributes the force more equally.

- Offers better stability

- Suitable for larger bearings

- Provides a more even pull

Three-jaw pullers are great for larger and tougher bearings. They are more stable but can be more challenging to set up. Ensure all three jaws are evenly spaced for the best results.

Internal Bearing Pullers

Internal bearing pullers are used for bearings inside a housing or casing. They grip the inner race of the bearing. The tool expands inside the bearing to hold it securely.

- Ideal for bearings in tight spaces

- Grips the inner race of the bearing

- Useful for blind holes

Internal bearing pullers are specialized tools. They are perfect for removing bearings from hard-to-reach places. These pullers can be more complex to use but are very effective for their specific purpose.

Safety Precautions

Use a puller to remove a bearing from a shaft safely. Make sure to wear safety goggles and gloves. Secure the puller properly to avoid accidents.

Removing a bearing from a shaft with a puller can be tricky. Follow safety precautions to avoid injuries and ensure a smooth process.

Personal Protective Equipment

Wear safety glasses to protect your eyes from metal fragments. Use gloves to shield your hands from sharp edges. Wear steel-toed boots to protect your feet from heavy items. Ensure your clothing fits well and is not loose. Loose clothing can get caught in machinery.

Work Area Preparation

Clear the work area of any debris. A clean workspace prevents tripping and slipping hazards. Ensure proper lighting to see clearly. Poor lighting can lead to mistakes. Keep tools and materials organized. An organized area reduces the risk of accidents. Make sure your puller is in good condition. A faulty puller can cause injuries. “`

Preparation Steps

Removing a bearing from a shaft requires careful preparation. Proper steps ensure safety and efficiency. Let’s break down the key preparation steps.

Inspecting The Bearing And Shaft

First, check the bearing and shaft. Look for wear, rust, or damage. Damaged parts need replacement. Clean the area around the bearing. Ensure there are no obstructions. This inspection helps you understand the condition of the parts. It also helps you plan the removal process.

Gathering Necessary Tools

Next, gather all necessary tools. You will need a puller for this task. Make sure the puller is the right size for your bearing. You might also need wrenches, screwdrivers, and a lubricant. Having all tools ready saves time. It also makes the process smoother.

Removing The Bearing

Removing a bearing from a shaft can be tricky. But with the right tools, it becomes easier. A puller is one of the best tools for this job. Let’s go through the process step by step.

Positioning The Puller

First, position the puller over the bearing. Make sure it is centered. The arms of the puller should grip the bearing firmly. Check that it won’t slip during use.

Applying Force Evenly

Next, apply force evenly. Turn the puller’s screw slowly. This will create a steady pull. Do not rush this step. Slow and steady wins this race.

Checking For Bearing Movement

As you apply force, check for bearing movement. The bearing should start to move along the shaft. If it does not, stop and reposition the puller. Then try again.

Dealing With Stubborn Bearings

Dealing with Stubborn Bearings can be a real challenge. Bearings can sometimes get stuck and refuse to budge. This can be frustrating, especially when you need to get the job done quickly. Below are some effective methods to help you deal with those stubborn bearings.

Using Penetrating Oil

Penetrating oil is a great helper. It seeps into tight spaces and loosens rust and grime.

- Spray the oil directly onto the bearing.

- Let it sit for a few minutes to work its way in.

- Try using the puller again after the oil has had time to work.

This method can make a big difference. Penetrating oil can save you time and effort.

Applying Heat

Heat can help expand the metal, making it easier to remove the bearing.

- Use a heat gun or a propane torch.

- Apply heat evenly around the bearing for about 2-3 minutes.

- Be careful not to overheat and damage other parts.

- Try using the puller again while the bearing is still warm.

Heat works well for stubborn bearings. Just be cautious to avoid burns.

Alternative Methods

If oil and heat don’t work, try these alternative methods.

| Method | Description |

| Cold Spray | Use a cold spray to contract the bearing, making it easier to remove. |

| Hammer and Chisel | Gently tap around the bearing to loosen it. Be careful not to damage the shaft. |

| Hydraulic Puller | Use a hydraulic puller for extra force. This can be more powerful than a regular puller. |

These methods can be very effective. Use them when other techniques fail.

Post-removal Procedures

After removing a bearing from a shaft with a puller, several important steps follow. These steps ensure the continued performance and longevity of the machinery. Paying attention to these details helps prevent future issues and ensures smooth operation.

Inspecting The Shaft

First, inspect the shaft thoroughly. Look for any signs of wear or damage. Scratches, dents, or rust can affect the new bearing. Address any issues before proceeding.

Cleaning And Lubricating

Next, clean the shaft. Use a clean cloth to remove dirt and debris. Apply a suitable cleaning agent if necessary. Once clean, apply a thin layer of lubricant. This helps the new bearing slide into place easily. It also reduces friction and wear during operation.

Replacing With New Bearing

Finally, replace the old bearing with a new one. Ensure the new bearing matches the specifications. Align the bearing correctly with the shaft. Gently slide or press the bearing into place. Ensure it sits snugly without any gaps.

Common Mistakes of Remove bearing puller

Removing a bearing from a shaft with a puller can be tricky. Many make common mistakes that lead to damage or injury. Knowing these mistakes helps you avoid them and ensures a smooth process.

Using Incorrect Puller Type

Choosing the wrong puller is a frequent error. Pullers come in various sizes and types. Using the wrong one can damage the bearing and shaft. Always match the puller to the bearing size and type. Read the manual or instructions to ensure a proper fit.

Applying Excessive Force

Many believe more force will make the job easier. This is false. Excessive force can damage the shaft, bearing, and puller. Apply steady, even pressure to remove the bearing. If it resists, check for proper alignment and fit. Never rush the process.

Ignoring Safety Measures

Safety is crucial but often overlooked. Not wearing protective gear can result in injuries. Always wear gloves and safety glasses. Ensure the puller is secure before applying force. A loose puller can slip and cause harm. Follow all safety guidelines to protect yourself.

Maintenance Tips of Bearing puller

Keeping your tools and equipment in good shape is important for efficient work. Here are some maintenance tips to help you remove bearings from shafts with a puller.

Regular Inspection

Regular inspection of your tools is essential. Check for any signs of wear or damage. This includes looking at the puller’s arms, screws, and jaws. Worn or damaged parts can affect the puller’s performance. Make sure to replace any faulty parts immediately. This will ensure your puller works well each time you use it.

Proper Storage Of Tools

Proper storage of your tools can extend their life. Always keep your puller in a dry, clean place. Moisture can cause rust, which weakens the tool. Use a tool box or cabinet for storage. This prevents dust and dirt from building up on the puller. A clean tool performs better and lasts longer.

Lubrication Practices

Lubrication is key for maintaining your puller. Lubricate moving parts regularly. This includes the screw and joints. Use a light machine oil or grease. Lubrication reduces friction and wear. It also makes the puller easier to use. Ensure to wipe off any excess oil to avoid attracting dirt.

| Maintenance Task | Frequency | Details |

| Inspection | Monthly | Check for wear and damage |

| Storage | After each use | Store in a dry, clean place |

| Lubrication | Monthly | Lubricate moving parts |

Frequently Asked Questions

How Do You Use A Puller To Remove A Bearing?

To use a puller, place its jaws around the bearing. Tighten the puller’s center bolt to pull the bearing off the shaft. Ensure even pressure to avoid damage.

What Tools Are Needed To Remove A Bearing?

You’ll need a bearing puller, wrench, and possibly lubricating oil. These tools help in safely and effectively removing the bearing from the shaft.

Can I Remove A Bearing Without Damaging The Shaft?

Yes, using a bearing puller ensures the bearing is removed without damaging the shaft. Apply even pressure and follow the puller’s instructions for best results.

How Long Does It Take To Remove A Bearing?

Removing a bearing with a puller usually takes about 10-20 minutes. This varies based on your experience and the bearing’s condition.

Conclusion

Removing a bearing from a shaft with a puller is straightforward. Follow the steps carefully. Use the right tools. Ensure safety at all times. By doing so, you can avoid damage. Proper technique saves time and effort. This guide helps in maintaining your machinery.

Always refer to the manual. Practice makes the process easier. The more you do it, the better you get. Happy fixing!

Read also: