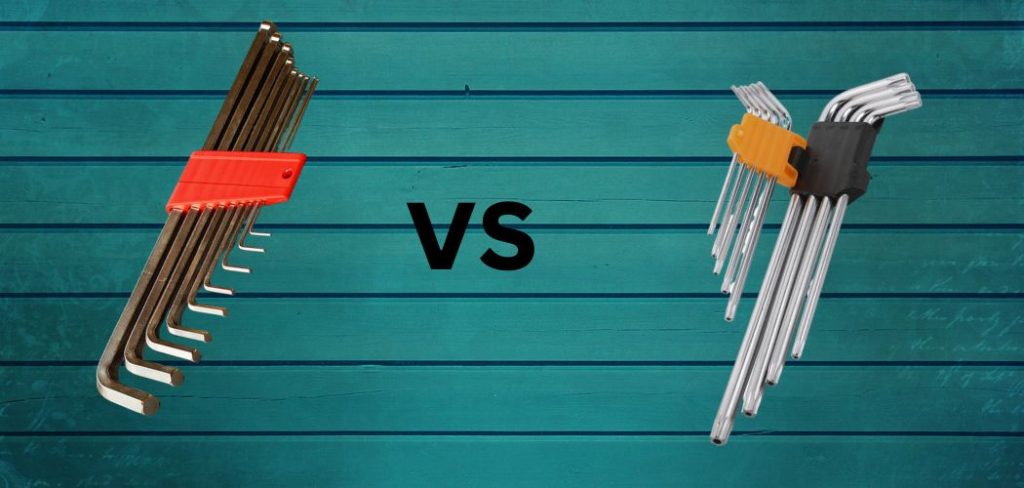

Allen Key Vs Torx

The difference between Allen Key vs Torx is quite a critical concept, so many people think they are the same. If you also think of them as such and want to get guidance on their correct use, then this article is just for you; then let’s start the main discussion.

What is the Purpose?

Allen Key

An Allen or hex key is a tool for tightening or loosening screws and bolts with hexagonal sockets. It features a hexagonal bar that fits into the socket and a handle for applying torque. It is used in furniture assembly, machinery, and more.

Allen keys come in various sizes and can be paired with socket wrenches. They provide efficient control over fastening hexagonal-head screws and bolts.

Torx Key

A Torx key, or Torx wrench, is for tightening or loosening screws and bolts with star-shaped Torx heads. It offers secure torque application, preventing head damage. Sized with a “T” followed by a number (e.g., T10, T25), it’s used in industries like automotive and electronics to prevent slippage and ensure reliable connections.

Torx keys provide durability and precision, which are vital for tasks requiring high torque and accuracy.

What is the Difference Between the Allen Key and Torx Key?

You should know the main difference between the Allen and Torx keys to distinguish them and get the proper benefit, so I am describing their main difference below.

Design and Shape

An Allen key is a simple L-shaped tool with a hexagonal cross-section. It is formed from a single piece of steel rod bent at a 90-degree angle, creating an “L” shape. The short arm fits into hexagonal screw sockets, and the long arm provides leverage for turning.

A Torx key, on the other hand, features a star-shaped pattern with six or more points (known as lobes). The Torx key is used to turn screws with corresponding star-shaped recesses.

Driving Mechanism

The Allen key applies torque through the perpendicular distance between the center of the screw and the point where force is applied. This results in rotational movement.

The Torx key also uses torque to turn screws, but its star-shaped pattern provides a greater surface area for distributing force. This design reduces the likelihood of the tool slipping out of the screw head (cam-out) and allows for higher torque application.

Resistance to Cam-out

Allen keys are more prone to cam-out when the tool slips out of the screw head under high torque. It can damage the screw head or the tool itself.

Torx keys are less prone to cam-out due to their star-shaped pattern and the more significant number of contact points between the tool and screw head. This feature enhances the grip and reduces the risk of damage.

Torque Transmission

Allen keys transmit torque through the length of the tool, which may lead to bending or breakage if excessive force is applied.

Torx keys transmit torque more evenly across the lobes, distributing the force and reducing the risk of breakage.

Applicability

Allen keys are commonly used for assembling furniture, bicycles guitars, and other household items. They come in a variety of sizes and are widely available.

Torx keys are commonly found in automotive, electronics, and industrial applications. They are often used when higher torque is required and cam-out must be minimized.

Security Variants

While there are security variants of Allen keys, such as tamper-resistant hex screws, they are not as widely used as Torx security screws.

Torx keys have various security variants, including tamper-resistant Torx (TR) and Torx Plus, which feature posts or additional lobes to prevent standard Torx keys from fitting.

Compatibility

Different sizes of Allen keys are required for different screw sizes.

Torx keys are available in a range of sizes, but they are often compatible with multiple screw sizes due to the design of the star-shaped pattern.

What is the Best Choice for Your Hex Vs Torx Key?

The choice between a hex key and a Torx key depends on the specific application and the type of fasteners you are working with. Here are a few considerations.

Hex Key (Allen Key):

- Choose a hex key when you are working with hexagonal (six-sided) screws and bolts.

- Commonly used for simple tasks like assembling furniture, bicycles, and household items.

- The torque offers a good balance and ease of use for small fasteners.

- Available in different sizes to match different hexagon socket dimensions.

- Suitable for a wide range of DIY and professional applications.

Torx Key:

- Choose a Torx key when working with Torx (star-shaped) screws and bolts.

- Ideal for applications where high torque and precision are required, such as in automotive and electronics.

- The design reduces cam-out risk (slippage), providing a more secure connection.

- Available in various sizes marked with a “T” followed by a number.

- Offers increased durability and resistance to stripping, making it suitable for demanding jobs.

What Materials Are Used for Making the Allen and Torx Keys?

Allen and Torx keys are made from carbon steel for affordability and durability. Stainless steel is corrosion-resistant, ideal for moisture-exposed areas. Chrome vanadium steel provides strength under high torque.

Alloy steel is suitable for heavy-duty applications. Titanium offers lightweight strength and corrosion resistance. Some tools use plastic or composite materials for exemplary assembly.

Why Do Many People Consider the Allen and Torx Keys the Same?

The confusion between Allen and Torx keys arises from their similar L-shaped design. However, it’s important to note that these tools have distinct designs tailored for different fastener types. Allen keys feature a hexagonal (six-sided) tip, while Torx keys have a star-shaped tip with multiple points.

This design discrepancy is crucial for correctly pairing the tool with the specific type of fastener you’re working with.

Can You Use Torx Instead of Allen?

While you can occasionally substitute a Torx key for an Allen key due to its similar L-shaped design, it’s not the most advisable practice. Allen keys have a hexagonal (six-sided) tip, while Torx keys have a star-shaped tip with multiple points. The difference in design can lead to issues such as a loose fit, the potential for stripped screws, or even damage to both the fastener and the tool.

For optimal results and to maintain fastener integrity, it’s best to use the recommended tool explicitly designed for the specific fastener type you’re working with.

Conclusion

While staying at my friend Suman’s motorcycle garage during a heavy rainstorm in our local market, I had the opportunity to research and write my article, successfully highlighting the differences between the Allen Key and Torx. If you have any differing opinions about the article, please share them by commenting below.

Read also:-